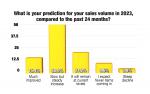

CHICAGO — While automation is increasing in both its availability and capability in drycleaning plants, many cleaners are still reluctant to make the decision to add this equipment to their plant. With continuing labor shortages, however, some cleaners are fighting their fears and forging ahead.

In Part 1 of this series, we examined the question of enhancing versus replacing labor, and how automation can make existing staff more productive. In Part 2, we compared the initial costs of installing automation with the return on investment cleaners can expect once they take the plunge. Today, we’ll conclude by looking what our cleaners are planning in the future, and how to combat the apprehension of trusting new technology.

A Continuing Evolution

Even though they have extensive automation in their plants, Seattle-based Helena Cleaners and South Florida-based Sudsies are both planning to add new elements in the near future.

“We are getting a dispatch conveyor we just purchased installed in September,” says Will Waterstraat, managing partner at Helena Cleaners. “Right now, without that conveyor, we have about three and a half to four people taking the clothes off the assembly conveyor and bagger, and then run and put them into routes. With the dispatch conveyor, we will end up getting probably about 1,500 square feet of floor space freed up that we can do something else with. But the best thing with that is, we’ll probably go down to one-and-a-half employees with the new system.”

This conveyor should also help the company’s drivers become more efficient.

“They rarely organize their van, but with the dispatch conveyor, it will optimize their route by stock,” Waterstraat says. “When they end up doing that, they won’t be hunting in the back of their vans, looking for orders. At the end of the day, I can only imagine it is going to save them probably an hour or two in their day.”

As for Sudsies, automated kiosks are the next step.

“We have one kiosk at one location now and within the next few months, we’re hoping to have another,” says Art Bai, the chief technology officer for Sudsies. “We will most likely never completely give up the human factor, but to use the banking analogy, most banks have ATMs that are available during business hours, so customers can choose to be waited on at the counter or use the ATM. That’s the kind of flexibility we are introducing now with these kiosks that, before long, will be installed in two different locations.”

Fears and Moving Forward

When making the decision about automating, Waterstraat advises cleaners who are considering this path forward to try to anticipate their needs of the next few years.

“Where do you see your business in three, five or 10 years?” he asks. “And not only that, but do you think that labor and government are going to get easier on businesses? For every new employee we add, we have more responsibilities put on us by the city and the state and the federal government. I’m more than happy to take on our responsibility and those needs, because we’re in business, but at the end of the day, it does cut into your margins.”

While Waterstraat has seen the evolution of automation through his 17 years in the drycleaning industry, he admits he was hesitant to embrace the technology at first.

“I think the toughest reason to pull the trigger on it is because it’s an unknown,” he says. “That was difficult for me to do, because we had been doing assisted assembly for so long. But leap forward to now after we’ve had it for two years, and I would not go back.”

Waterstraat believes cleaners can fight this fear of the unknown by contacting non-competing cleaners and learning from their experiences.

“I’ve reached out to a lot of dry cleaners,” he says, “and most of them want to share their experience. Almost everyone in the drycleaning industry wants to see the industry get better, because at the end of the day, our weakest link is a cleaner who doesn’t follow proper procedures, and something gets damaged. Then we, as a whole, take the reputation hit of not being good at what we do. And there are a lot of really good operators out there.”

For cleaners who fear that adding technology might change their business by eliminating the human touch, Christopher White, executive director of America’s Best Cleaners (ABC), an industry consulting firm that, among other services, provides plant design and redesign services, believes that this is not necessarily the case.

“I would tell cleaners that automation does not necessarily mean sacrificing personalization or customer service,” he says. “It can be an opportunity to redirect human resources to focus on areas where they can truly make a difference, such as customer service, quality control, and specialized cleaning tasks.

“By combining automation with a skilled workforce, cleaners can maintain the human touch and even elevate the level of service they provide.”

For Part 1 of this series, click HERE. For Part 2, click HERE.

Have a question or comment? E-mail our editor Dave Davis at [email protected].