MORRISTOWN, Tenn. — In early 2024, two significant players in the drycleaning industry joined forces when Forenta acquired Garment Management Systems (GMS).

The combination of Forenta's established manufacturing experience and GMS' innovative automation solutions means dry cleaners can now streamline their modernization efforts through a single source.

The deal, which culminated in a signing earlier this year, represented the endpoint of 10 months of careful negotiations between me representing Forenta and Brett McLeod for GMS. The path to agreement included my hands-on involvement in a 24/7 kiosk installation in Charlotte, an extensive evaluation of GMS’ Little Rock facility, and numerous discussions with partners and legal teams.

While the outcome wasn’t always certain, a deeper look at the histories of both companies reveals that this union may have been decades in the making.

The First Steps Toward Automation

The story begins in 1960s Indiana, where the drycleaning industry was humming, polyester leisure suits were still a decade away, and business was good for the equipment manufacturers. During this time, the Forse Corporation had established itself as a leader in pressing equipment manufacturing.

Under the direction of owner Don Forse, a mechanical engineer, the company’s innovative spirit drove the development of numerous groundbreaking products for the time. These innovations included the famous fastback drycleaning press, a patented laundry press head closing system, the upright pant topper and a coin-operated electrically heated press, among others.

Despite the industry’s robust health, however, Forse Corporation faced significant challenges at its Anderson, Ind., manufacturing facility. Recurring labor strikes hampered the company’s ability to meet growing equipment demand. This led Don Forse to accept a strategic proposal from Jack Fishman and the Morristown Industrial Board to establish a new manufacturing operation in Morristown, Tenn.

In 1961, Forco (later renamed Forenta) was established as the exclusive manufacturer of Forse Corporation’s pressing equipment, while the original company maintained its headquarters, engineering, sales and accounting operations in Anderson.

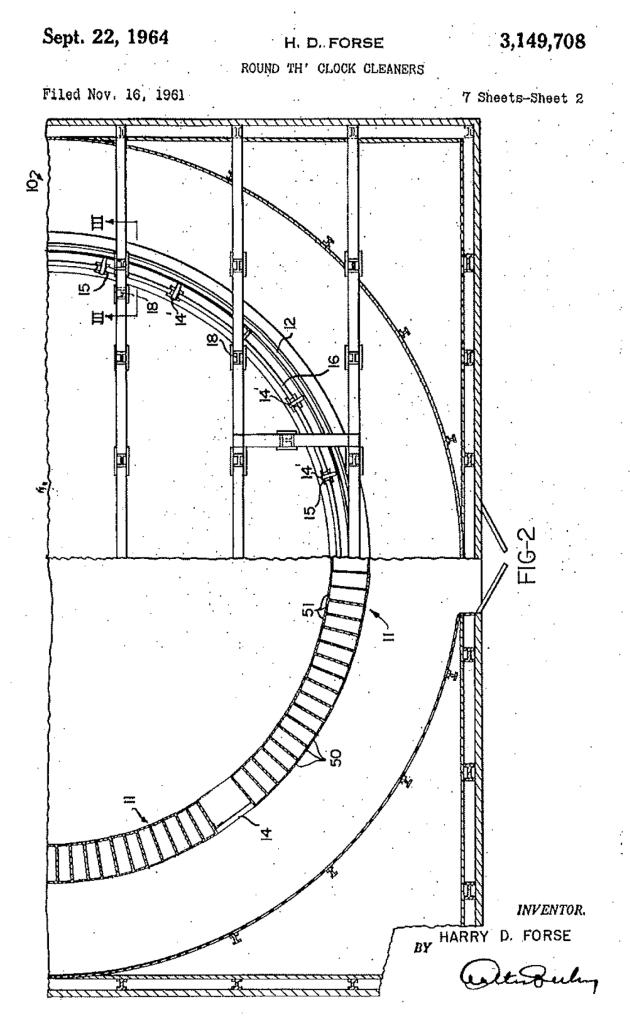

Freed from day-to-day manufacturing concerns, Forse and his engineering team continued their work. In a development that would foreshadow future industry trends, they created and patented the “Round the Clock Cleaners” system — a circular conveyor system designed to enable customers to retrieve their garments at any hour, potentially even in an unattended storefront — in September 1964.

The project, however, was ultimately shelved shortly after the patent was awarded. It is still unclear why Don Forse pulled the plug on the project. The most accepted theory is that he realized that the product was simply too far ahead of its time, and the technology needed to support such a product was not yet perfected.

This innovation, however, previewed the future of automated garment management by decades.

When the polyester trend of the early 1970s caused unprecedented declines in pressing equipment sales, Don Forse, believing the industry would never bounce back, dissolved the Forse Corporation in 1972 and sold its intellectual property to Forenta for a nominal sum.

Forenta’s survival through these challenging times was largely due to its manufacturing versatility, producing everything from furniture brackets to miniature boilers and small car haulers. When the industry began its recovery in the mid-1970s, Forenta emerged stronger, now producing equipment under its own brand under the Forenta logo and controlling its destiny from its Morristown headquarters.

The Modern Era of Automation

By 2002, Forenta had successfully diversified its operations through the acquisition of Saratoga Conveyor Company and the introduction of its own water chiller line. Building on this momentum, the company sought to develop a 24/7 garment pickup solution that would modernize the customer experience — an echo of the “Round the Clock Cleaners” system. This led to a partnership with Italian firm ACS Engineering (ACS) and an installation project in Little Rock, Ark.

This installation caught the attention of McLeod, a chemical engineering consultant who was a friend of the store’s owner. A graduate of Auburn University, McLeod brought 15 years of experience in various engineering projects, including waste incineration and disposal systems, and had previously managed a perc production plant in the mid-1980s.

His self-described identity as a “production guy” drew him to the challenges presented by his friend’s ACS system installation. The fact that Forenta and the store owner had difficulty perfecting the system intrigued him even more. He wanted to see the system working to its full potential. McLeod soon founded HMC Solutions (later GMS) with the goal of developing a more effective and economical kiosk conveyor system.

Fast forward a few years, and many prototypes later, and McLeod’s persistence led to successful implementations of not only a patented 24/7 kiosk conveyor system, but an automated assembly conveyor, as well.

Meanwhile, Forenta’s partnership with ACS Engineering ultimately proved unsuccessful, leading the company to refocus on its core business lines of pressing equipment, storage conveyors and water chillers. No more thought was given to developing a 24/7 kiosk conveyor system — until that fateful first conversation between McLeod and me in July 2023.

A Circle Completed

Forenta’s acquisition of GMS represents more than just a business transaction — it marks the convergence of two parallel journeys in innovation. The deal brings together Forenta’s manufacturing expertise with GMS’ automated systems technology, effectively realizing the vision first glimpsed in Don Forse’s 1964 patent.

The combination of Forenta’s manufacturing capabilities and GMS’ innovative technology positions Forenta to better serve the evolving needs of the drycleaning industry. This partnership demonstrates how innovation, even when ahead of its time, can lay the groundwork for future success.

For industry veterans who remember the challenges of the 1970s polyester era, this latest development shows how adaptability and innovation continue to drive the industry forward. Forenta's acquisition of GMS stands as a testament to the industry’s resilience and ongoing evolution, bringing together decades of experience with modern automation technology.

When visitors stop by the Forenta booth at industry trade shows, they’ll now see a company that represents both historical legacy and future innovation. The union of Forenta and GMS, while seeming unlikely at first glance, represents the culmination of a story that began 64 years ago with a labor strike, was revisited through a product development effort in 2002, and finally came to fruition in 2024 — a testament to how innovation and determination can come full circle in unexpected ways.

Have a question or comment? E-mail our editor Dave Davis at [email protected].