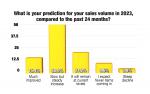

CHICAGO — While many dry cleaners have been thinking about using more automation in the processes for years, the recent drop in available labor has forced many to move their timetable up and take a leap earlier than they might have anticipated.

In Part 1 of this series, we examined the question of enhancing versus replacing labor, and how automation can make existing staff more productive. Today, we’ll continue by comparing the initial costs of installing automation with the return on investment cleaners can expect once they take the plunge.

Upfront Costs and ROI

Christopher White, executive director of America’s Best Cleaners (ABC), an industry consulting firm that, among other services, provides plant design and redesign services, understands that automation can seem expensive at the outset. He urges cleaners considering adding equipment should look at this as a long-term investment — one that will pay off and give the business an advantage for future growth.

“In the design process, you must start with the end in mind and work backward,” he says. “We like to start with your 10-year goal, especially if you are buying the property, and then work back to seven, five, or three years and develop financial and developmental triggers. This allows you to budget your investments and upgrade as the business calls for it.”

Will Waterstraat, managing partner at Seattle-based Helena Cleaners, made these calculations when building a new a 20,000-square-foot plant, and was able to design in automation, including an assembly conveyor, bagger and distribution conveyor.

“Automation can be a really big expense,” he says. “The distribution conveyor and the assembly conveyor, together, were $240,000. That’s not a small expense. But then you realize how fast you’re going to be able to pay that off. We went down from four employees to one and a half. In Seattle, on average, one employee a month is probably about $4,000. So that’s instantly almost $12,000 a month back. So, you start thinking about what your payment is on it, and it starts making sense.”

“A lot of people see a dry cleaner who is fully automated, and they think, ‘Wow, that’s a lot of money,’” says Luis Moreno, general manager of South Florida-based dry cleaner Sudsies. “And, yes, it is a lot of money. But they also think they will have to do everything at once, and they don’t. They could start with one automated system, and evolve into another one and another, and eventually they become fully automated. I also think they will see the benefits on day one. That’s the way we did it. Everything was an evolution. We started with one, and we kept adding on.”

It’s also important to recognize that there are different options when it comes to automation, says Art Bai, the chief technology officer for Sudsies.

“There are a number of players in the automation industry, and it’s not a one-size-fit-all situation,” he says. “I would say the very first thing to look at is your volume and your true needs. You can take a Mercedes out to the grocery store for a five-minute round trip, but is that really the best use of your money and the technology? It’s important to know the options, but it’s also important to really have a long, hard look at your production numbers and see what fits best.”

The Path to Automation

When deciding to embark on the path to automation, certain elements are going to give cleaners more immediate results than others. This “bang for the buck” element can ease the transition, says Jason Loeb, president of Sudsies.

“The first step, which costs the least, is bar-coding the items,” he says. “If you’re not bar-coding, you can’t track it, and you can’t bag it. Without this, there is no automation.”

Once that element is in place, Waterstraat says that an assembly conveyor that sorts and bags the orders will make the biggest difference in maximizing labor efficiencies.

“We previously had assisted assembly, and it would easily take three to four people daily, putting those orders together and bagging them, with the possibility of making mistakes,” he says. “With assisted assembly, you really limit the number of mistakes that are getting made. Also, when you take out the manual labor of the bagging, it becomes a much faster process.”

Cleaners should also keep their eye out for new technology, because the pace of development is only getting faster.

“I recently witnessed a four-buck carousel pants tension topper/legger that could produce 250-plus pants an hour of reasonably good quality in a large dry cleaner,” White says. “These could be game changers in today’s tight labor market.”

Loeb estimates that the technology at his company has reduced the need for labor there by 40 or 50 employees.

“Our technology has allowed our pressers to go faster, for example, which reduces labor costs,” he says. “As soon as we put that in the system, it caused a higher piece-per-hour rate, and a higher piece-per-hour rate requires fewer pressers.”

Tempering Expectations

Whatever technology is installed, Bai says, cleaners need to have reasonable expectations of their equipment.

“That automation — that bagger or conveyor — is there for you 363 days a year,” he says. “It’s going to be your best employee. It’s not going to walk out on you. It’s not going to call in sick, and it’s not going to ask for a raise. It will always show up and will always do the work. That’s the good news. The bad news is that there will always be a couple of days a year when you just want to scrap the whole thing and throw it in the river. You’ve got to take the good with the bad, because there’s a lot more good, and the return will be amazing.”

Waterstraat found that there was a period of adjustment and growing pains when first switching on the new equipment.

“The first week, we realized that our poly wasn’t rolled correctly,” he says. “If it’s not rolled correctly, it doesn’t bag correctly, and then it just stops the flow. We had to find a producer that has very consistent poly. You have to have good hangers, and you have to have good poly. You learn that in the process. Once you’re getting consistent supplies, those issues become nonexistent.”

Come back Tuesday for the conclusion of this series, when we’ll look at the future of automation and fighting the fear in moving forward. For Part 1 of this series, click HERE.

Have a question or comment? E-mail our editor Dave Davis at [email protected].