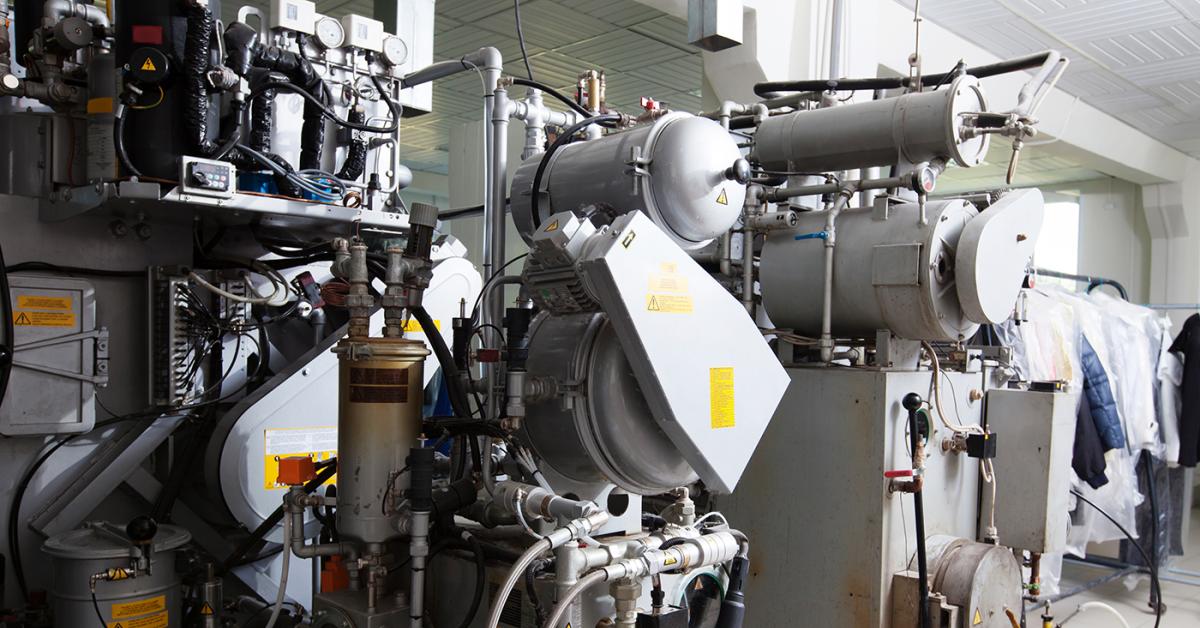

CHICAGO — It’s bound to happen at some point. The machine you depend on to get your customers’ garments from intake to delivery goes down. Maybe that machine was hanging on by a thread, or maybe it came out of the blue. Either way, a decision has to be made to repair or replace it.

In Part 1 of this series, we examined topics such as various factors that can lead an owner to contemplate buying new machinery and how to future-proof their investments the best they can. In Part 2, we examined the evergreen question of “Repair or Replace” when it comes to dealing with aging equipment. Today, we’ll conclude by looking at the advantages of buying new equipment, and potential issues when it comes to putting those machines into your plant.

New Equipment, New Possibilities

When replacing older machines or adding to the company’s inventory, new equipment can often lead to new profit potential. By working with the manufacturer or supplier, cleaners can make the most of this benefit.

“As a manufacturer, we should be able to tell them what items we can clean, and what new items we can clean,” says Vic Williams, Eastern sales manager for Union Dry Cleaning. “Maybe they were using a solvent that really couldn’t clean certain items. By us helping them out that way, they may be able to get into another market of cleaning things they never cleaned before.”

This added capability is something that the cleaner can promote to customers to keep current clients happy and attract new business.

“Perhaps they can tell their customers that now they can clean leather, for example,” Williams says. “I’ve seen a lot of cleaners have to turn down leather work because they couldn’t do it.”

This expansion into new areas is made easier if cleaners are coached on how best to use their new tools.

“Purchasing new equipment is a significant investment,” says Paulo Rocha, head of sales, HCS Business Unit for Miele Professional, “so it’s important to partner with a manufacturer that is going to take time to understand your needs and will offer hands-on training to ensure you get the maximum performance out of your machine to achieve your desired results.”

Hidden Costs

When making a big change in the equipment essential for the operation of the business, there will often be hidden costs associated with getting it up and running. Wesley Nelson, president of Sankosha USA, believes that planning ahead can lessen the impact.

“A lot of times, the dry cleaners should try to coordinate delivery and installation when it’s convenient for them, and not worry so much about if it’s convenient for the manufacturer,” he says. “They should really do it based on their schedule and their timetable. Consider a long weekend like Labor Day, for example. Everybody wants to take off and relax, but sometimes that’s a great time to install equipment because it doesn’t upset your production.”

Organization is key for a smooth install, Nelson says: “The cleaner can also ask how much time it is going to take, and then make plans accordingly. The more prepared you are, the less urgency comes into play.”

Another thing is to consider how this new equipment could impact the cleaner’s workflow.

“If you’re doing shirts, for instance,” Williams says, “asking questions like, ‘Before, I had the X brand model and now I’m going to have your model. Is the washing the same or is it different?’ And if it is different, then you need to get your soap or chemical company involved to come and help reprogram your machines. If you’re proactive about all that, while people are there to train you, you’re not also messing around with adjusting the washing machine.”

Navigating the Learning Curve

To bring out a new piece of equipment’s full potential, the owner and the people who will operate it need all the information they can get, and the manufacturer or distributor should be willing to provide this knowledge.

“In general, most new equipment will require some sort of training so that operators fully understand how to use the machines,” Rocha says. “This training could be as simple as reviewing the general operation of the machine, or it could be something more specific, like reviewing the programmability and how to fine-tune to specific needs of the product or wash. This might take some time upfront but will allow operators to offer the best results for their customers.”

“If the startup is done precisely by the manufacturer or the distributor who sells the machine, that’s the key to make the machine run really well,” Williams says. “You go through the whole machine with the customer, and when I say ‘customer,’ I mean the owner of the plant.”

He stresses that, while the owner might not be operating the machine, he or she needs to have a fundamental understanding of it.

“So many times, we’ve gone in and the owner will just say, ‘Train my guy,’” Williams says. “Well, that person leaves in six months, and nobody has a clue about the machine. If you’re the owner, you’re the one buying this piece of equipment, so please be attentive when someone comes to train.”

While this might mean the owner has to clear some time in his or her schedule, it is an investment in both the equipment and their company.

“A good startup can last anywhere from a few hours to a couple of days,” Williams says. “The manual is a good place to start, but a hands-on teaching session is better. Also, if they’ve devoted the time to be there with you and show you the machine, there’s no such thing as a stupid question. A good startup will eliminate 98% of the callbacks and problems that may occur over the phone.”

For Part 1 of this series, click HERE. For Part 2, click HERE.

Have a question or comment? E-mail our editor Dave Davis at [email protected].