CHICAGO — In the spring of 2020, when the pandemic dropped the bottom out of the drycleaning industry, owners dreamed of the day when society would reopen, business would pick back up and things would return to normal.

While the first two dreams have, to a certain degree, come true, things are still far from normal.

The supply chain that cleaners rely on for the materials necessary to do their work has been strained to —and in some cases far beyond — the breaking point. Items that once took days to weeks to deliver are now taking months, if they’re available at all. Cleaners and suppliers around the country are feeling the pinch.

“Really, anything coming in overseas is the biggest problem,” says Mike Ross, president of the New England division of Minda-AristoCraft. While his supply company is serving its customers the best it can, 2021 is proving to be a different type of challenge from the previous year.

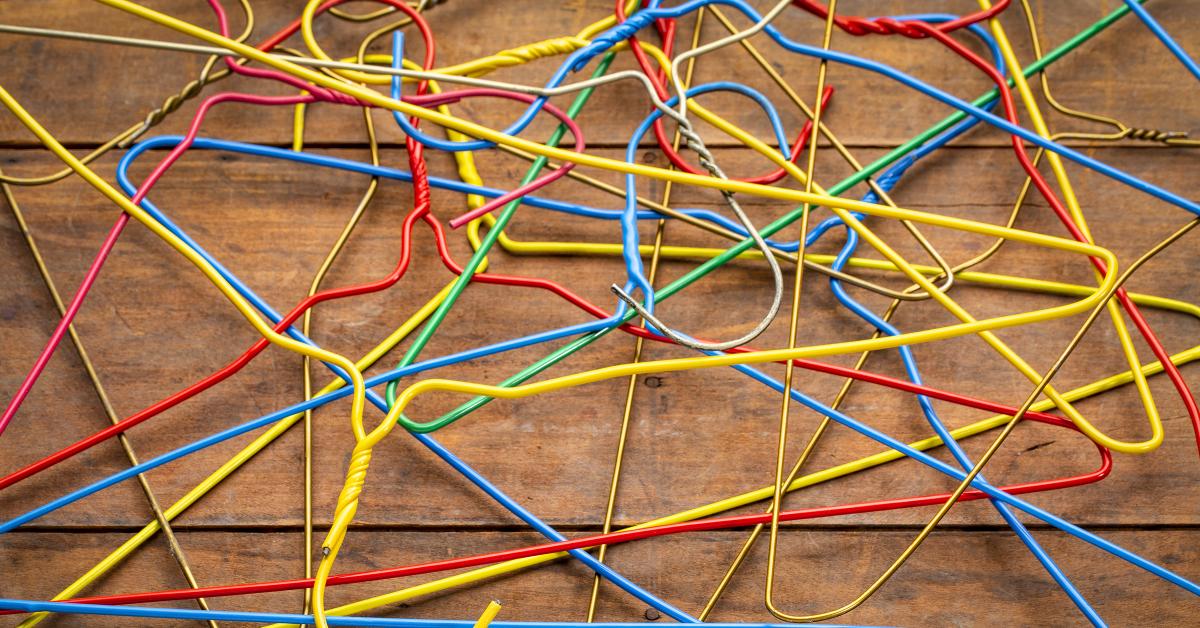

Hanging On

The biggest challenge currently is an item that is painfully necessary for customer satisfaction. “Hangers, in particular, are a problem because a great amount of them were coming in overseas,” Ross says. “It’s the shipping lines that have caused all these problems.”

“There are a lot of workarounds you can do for other products,” says Nora Nealis, executive director of the National Cleaners Association (NCA), “but how do you work around not having hangers? If poly is a problem, you can say, ‘Well, I’ll go for reusable bags, or play the environmental card.’ If your regular soap isn’t available, you can try out one that is. But with hangers, what do you do? Fold it up and give it back to the customer?”

This particular shortage was not immediately felt as the pandemic took hold of the nation.

“When it first started, I don’t think there were major supply issues,” says Peter Blake, executive director of the South Eastern Fabricare Association (SEFA). “I think everybody could get what they needed. Most people planned on having enough for the next three weeks, and when business fell apart, it fell apart fast. What you already had lasted a lot longer than you thought it was going to. When you thought you had a three-week supply, you found you actually had a six- or nine-week supply.”

As immunizations helped reopen society and business started to pick back up, however, those limited supplies began to demand attention.

“They didn’t need as many hangers when we were in the throes of the pandemic, when the problem was just getting the business,” Nealis says. “Now that the business is coming back, a lot of cleaners are trying to play catch up. But how do you deliver on your promise without the supplies you need in order to do business? There are cleaners who are trying to recycle hangers, and that’s helping a little, but it’s not ideal. It’s painful.”

“On the whole, it’s almost like somebody flipped the light switch on and said, ‘OK, everybody back to work,’” Blake says. “Now, we’ve got all this business coming in, which is great, but everyone is looking for products at the same time.”

Part of the problem isn’t necessarily a shortage of hangers — although rising demand for steel is also starting to impact the market. The challenge is getting the existing stock to the right place. Shipping is proving to be a massive bottleneck.

“Before COVID, you had all these containers on the water that were in this cycle of arriving, getting through the port, getting to their destination to be emptied, and then circling back to Asia to get filled up again,” Ross says. “When the pandemic hit, you had massive backlogs at the ports to get the containers unloaded; the ports were depleted of help because of health issues.”

This shipping cycle, which normally runs without incident, quickly started to break down. “The products were not getting to the end users as quickly, and they weren’t getting unloaded as quickly because the supplies weren’t needed,” Ross says. “So, you have this big backlog of containers not getting back to Asia, and products in Asia can’t ship back here because they don’t have any empty containers to put them in.”

So, how bad is the backup? “Hanger containers that were reliably 60 to 75 days from point of order to getting to the warehouse started taking, at best, five months,” Ross says. “I’ve got containers that I’m receiving in July that I ordered in October of last year.”

And, when demand starts to outstrip supply, increased prices are sure to follow. “Adding insult to injury is the cost per container,” Ross says. “To ship to me in Massachusetts, which is probably one of the more costly places to ship from Asia, container freight 12 months ago was about $5,500. Now, it can cost between $18,000 and $22,000 just to get available space.”

Home Field Advantage?

Foreign-sourced hangers weren’t the only ones impacted by the pandemic. Even though Leeds, Alabama-based M&B Hangers produces hangers domestically, they still were rocked by the upheaval in the industry.

“At the beginning of 2020, things were going on as they always had, and the supply chain was in flow,” says Mack Magnus, vice president of M&B. “There might have been a hiccup here or there, but they were isolated. Once the pandemic hit, though, purchases weren’t being made because the business wasn’t there to support it. For us, that meant that we had to ‘right size’ our business.”

And now that demand has increased, Magnus’ company has ramped production back up.

“We are back to pre-pandemic production and are currently working to add production to fill the gaps in the market,” Magnus says.

The limiting factor Magnus is seeing at the moment? Raw materials and transportation.

“We’re working to grow our business and increase manufacturing, but at the same time, we also need our steel vendors and our paper vendors to work and grow their business,” Magnus says. “Transportation and everything involved on the input side needs to come back.”

Come back next Tuesday for Part 2 of this series, where we’ll examine some recommendations for dry cleaners on how to handle shortages.

Have a question or comment? E-mail our editor Dave Davis at [email protected].