CHICAGO — The continuing problems with the global supply chain are causing many dry cleaners to rethink how they use supplies in their plants and re-examining their relationship with their vendors. As they get harder to obtain, once-common materials for everyday use have suddenly become a source of concern for many. Based on the answers we received from our American Drycleaner “Your Views” survey, the key for cleaners to get what they need is to have a good relationship — or a partnership — with their suppliers.

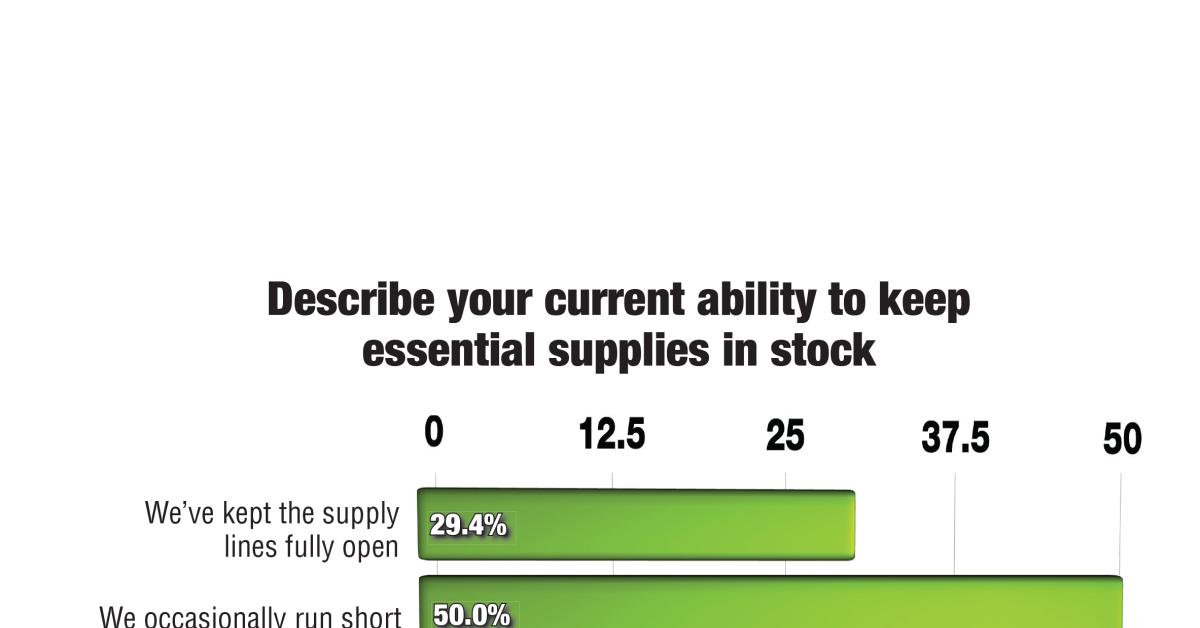

When asked about their current ability to keep essential supplies in stock, most of the respondents have managed to avoid a crisis, with half (50%) reporting that they “occasionally run short,” while 29.4% have “kept the supply lines fully open.” Of those who are encountering more broken supply chain links, 16.2% say they “often scramble to keep up,” 1.5% are “usually out of something” they really need, and 2.9% are “constantly out of critical supplies.”

Of the supplies our respondents are finding the most challenging to keep in stock, hangers (46.8%) and hanger struts (30.6%) topped the list by a wide margin. Other highly sought-after items included detergents and chemicals (8.1%), while equipment and repair parts tied with wedding gown boxes at 4.8%. Rounding out the list was poly at 3.2%, with 1.6% responding that they weren’t having a supply challenge at all.

One of the results of these supply chain issues is rising costs, as the law of supply and demand asserts itself. When asked to describe the impact of rising supply costs on their business and how they were dealing with it, many of our respondents said that they were raising their own prices and passing it along to the consumer. Answers included:

- “A good manager will monitor fluctuations in availability and cost; they make necessary adjustments. A poor manager will continue operations ‘as usual,’ with changes coming only in response to the competition. Adapt and overcome.”

- “I tried to get ahead of the game in August 2021 — we did a 15% price increase across the board. Then in February 2022, we did another 3% price increase. Also, we reuse as many hangers as we can that our clients bring back to us.”

- “It is not that we are unable to obtain the supplies we need, but the situation has caused us to work much harder to find what we need, and the cost of those supplies is the real issue. The costs are off the charts.”

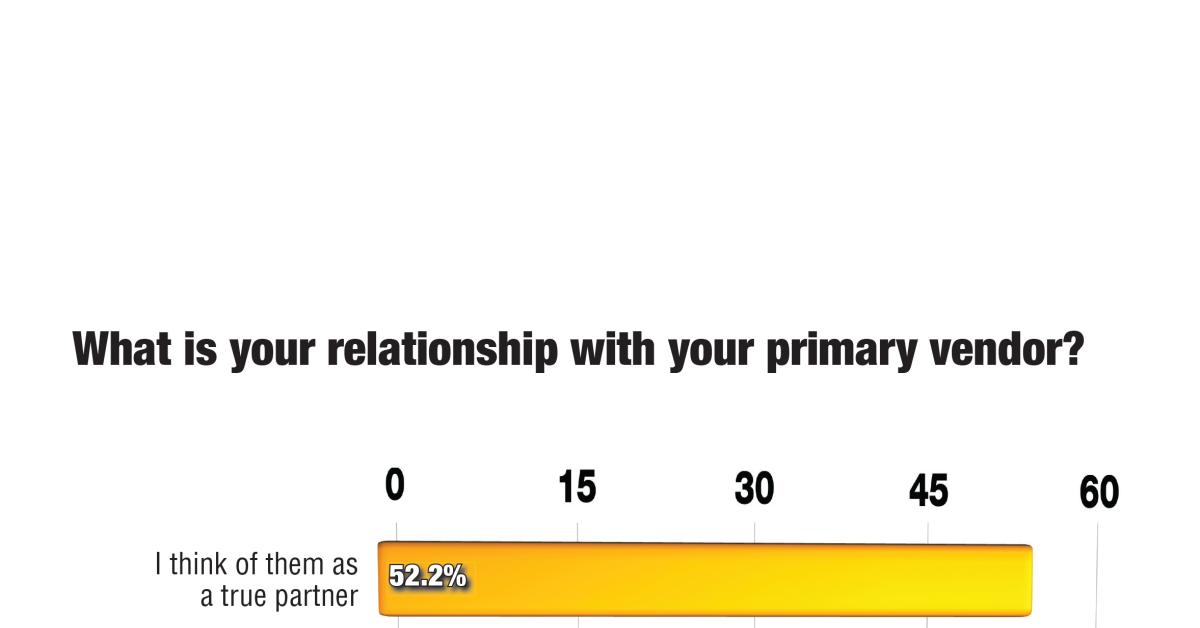

Maintaining a positive relationship between their suppliers can make the difference between dry cleaners having what they need to operate and always being on the short end, and based on our poll results, our respondents embrace this concept. When asked to describe their relationship with their primary vendor, more than half (52.2%) say that they “think of them as a true partner,” while more than a third (35.8%) report that “they are usually there when I need them.” Only 7.5% say that the relationship “could be improved,” while 4.5% are “looking for a new vendor.”

So, what qualities do cleaners look for in their vendors? “Communication” featured in many of our respondents’ answers:

- “Keeping me advised of his company’s ebb and flow, so I can plan accordingly. I am looking six weeks out to have the opportunity to fill any gaps that develop.”

- “Honesty, even when the news isn’t good.”

- “Trusted advisor. Friend. There for you. Respond quickly. Get creative.”

- “Communication prior to something becoming a major issue, and assistance in finding alternative products.”

The “Your Views” survey offers a current snapshot of the trade audience’s views. The publication invites qualified subscribers to American Drycleaner emails to participate anonymously in the unscientific poll each quarter.

Have a question or comment? E-mail our editor Dave Davis at [email protected].