RANDOLPH, N.J. — A cooling tower is a simple device used by many dry cleaners to cool their dry cleaning machines (DCM).

Cooling towers are a relatively inexpensive and dependable means of removing heat from DCMs. There are other ways to cool your equipment, but if you are paying for electricity and water, a cooling tower is often the most economical.

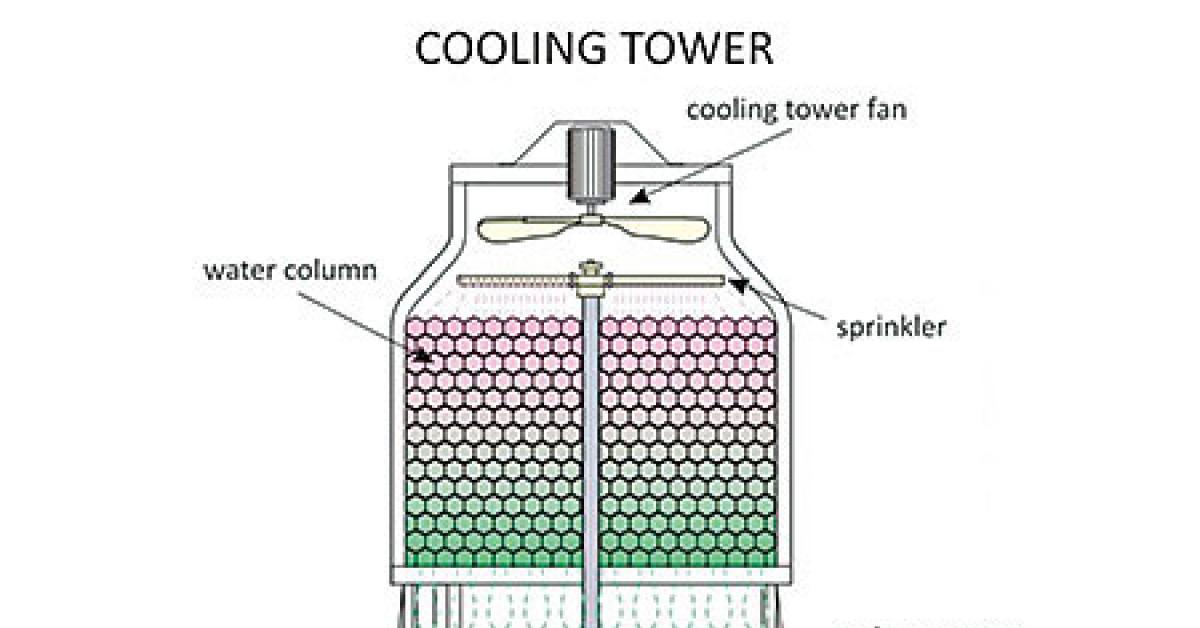

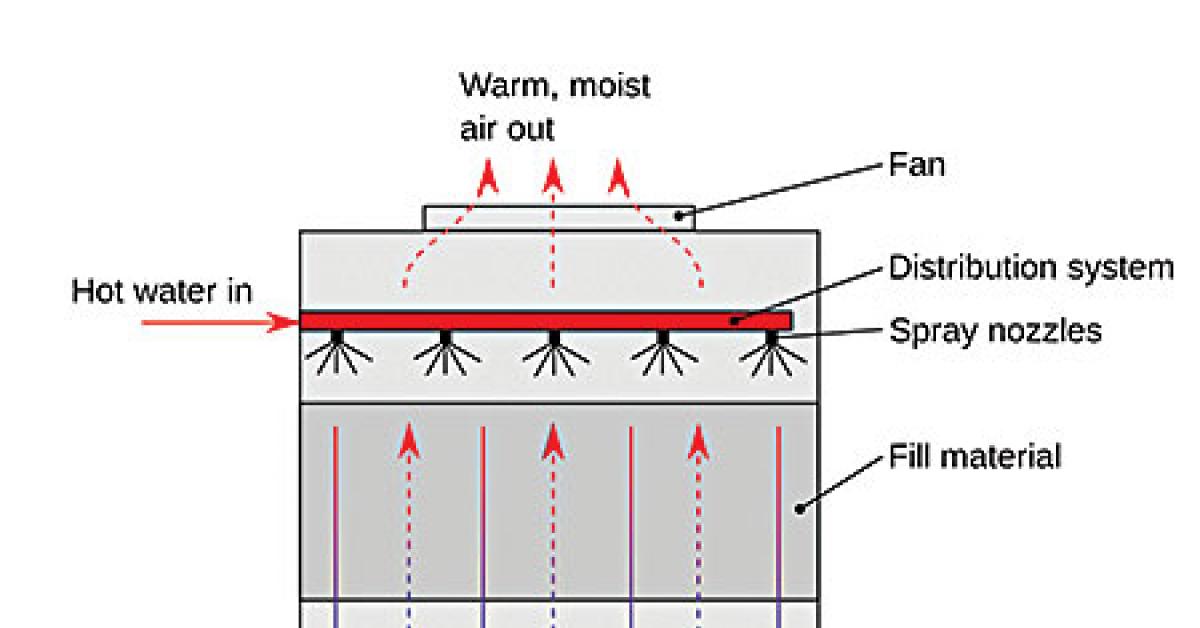

Cooling towers use the outside air to cool water which is circulated through the DCM’s refrigeration heat exchangers, still condensers and/or solvent coolers. (See Diagrams A and B.)

HOW IS THE COOLING TOWER WATER QUALITY MAINTAINED?

First, let’s understand the different types of solids in water, using the following simple examples:

Add sugar to a glass of water and stir. The initial teaspoon of sugar dissolves completely in the water. It is not visible, but it’s there. The sugar that is in solution is called “dissolved solids.”

As you add more and more sugar, the water becomes saturated and the sugar no longer dissolves. It begins to swirl in the water as you stir it and drops to the bottom when you stop. The sugar that swirls when you stir the glass is called “suspended solids.”

The sugar that drops to the bottom of the glass is called “precipitation.”

Dissolved Solids — As previously discussed, makeup water is continually added to replace water lost to evaporation. All makeup water has some level of dissolved solids. When the water evaporates, the existing dissolved solids remain behind in the system.

When more makeup is added, you get more solids, increasing the concentration of dissolved solids. Continue that process and you rapidly build up more dissolved solids. Left unmanaged, they will ultimately cause scaling.

It is essential to maintain low levels of dissolved solids in the cooling tower system water. We do this by checking the “conductivity” of the water with an inexpensive device called a “conductivity meter.”

The more dissolved solids in the water, the higher the conductivity. The concentration of dissolved solids is controlled by bleeding small amounts of water out of the storage tank. The more water we bleed, the lower the conductivity and the lower the dissolved solids.

Suspended Solids — As the water travels through the tower, it comes in contact with large volumes of outside air. The air is not always clean. Dirt from the air can mix with the water but not dissolve. These are called “suspended solids.” Over time, the concentration of suspended solids can increase. Since the cooling water is being circulated through several expensive coils in the DCMs, some of the suspended solids can cause fouling, causing the flow to slow.

This is not a good thing for the operation of the DCMs. Suspended solids can be managed by bleed-off and by draining and cleaning the cooling tower system one to two times a year.

Bacteria — Bio-growth is generally a result of suspended solid infiltration in the form of spores and/or other airborne growth. In city areas, grime, dirt and roofing materials can all contribute to the growth of bacteria in the cooling water.

The water you use to fill the cooling tower system and the water you use as makeup contains various forms of bacteria in low concentrations. Most dry cleaners shut off the tower when the drycleaning operations are complete.

In addition, most dry cleaners do not clean on one or two days per week and on holidays. Wet surfaces, heat, air contamination, suspended and dissolved solids can all contribute to the growth of bacteria. The bacteria buildup looks like a wet, dark green slime or mold.

Excessive bacteria buildup is a double threat: it can plug up the sprinkler arms, piping, and storage tank, interfering with water flow; and it can become airborne leaving the tower with the drift which can result in health issues for people who are exposed to that air.

Bacteria can be controlled by both proper cleaning/bleed-off, and by treating the water with chemicals designed for cooling tower water.

The manufacturers of these chemicals have representatives who can help the dry cleaner with the proper treatment. If the tower system is treated with a biocide, employees or contractors should wear recommended personal protection equipment (PPE) when working on the tower. In some areas of the U.S., special certifications are required to handle biocides.

pH — Another result from airborne contamination is the acidification of the cooling tower system water. This is caused by acid rain and or the incursion of nearby stack emissions containing sulfur-based soot.

This material pushes system water pH to the acid side. Without adequate chemical treatment (corrosion inhibitors), the acidic water will corrode the metals surfaces where the water is circulated.

Some dry cleaners simply add liquid chlorine bleach to kill the bacteria. Liquid chlorine will kill the bacteria, but maintaining a high concentration of chlorine can raise the alkalinity of the water, causing the copper coils in the DCMs to corrode faster than normal.

The best solution is to maintain a neutral pH of 7.0, a balanced level of biocide to kill the bacteria, an anti-corrosion additive, and a low level of chlorides.

HOW DO I CHECK THE CHEMISTRY OF THE WATER?

Many owners might say, “I’m not a chemist. How can I check the water?”

The answer is, dry cleaners are chemists! Dry cleaners have to maintain their solvent quality, mix and match laundry additives for various wetcleaning operations, and use a variety of chemicals on the spotting boards.

Operators with cooling tower systems check their water pH and chlorine levels with swimming pool strips. They have inexpensive meters that they use to measure conductivity.

In addition, two to four times a year, they take a sample of their tower water to a nearby lab to check their water quality. Recommended lab tests are for total bacteria and Legionella. (Oh no! A lab test! But once you learn to do it, it becomes just another thing you do to maintain your equipment.)

All of this may sound overwhelming, but it’s not! Owners use the proper levels of chemical additives to clean and disinfect their towers once or twice a year. They keep an eye on the tower operation, and they maintain their equipment in accordance with the manufacturer’s recommendations.

These operators are rewarded with 20-30 years of economical service from their cooling tower systems.

The author acknowledges that much of the information in this article was provided by Scott Pariser, Pariser Industries, Inc.

To read part 1, go HERE.

Have a question or comment? E-mail our editor Dave Davis at [email protected].