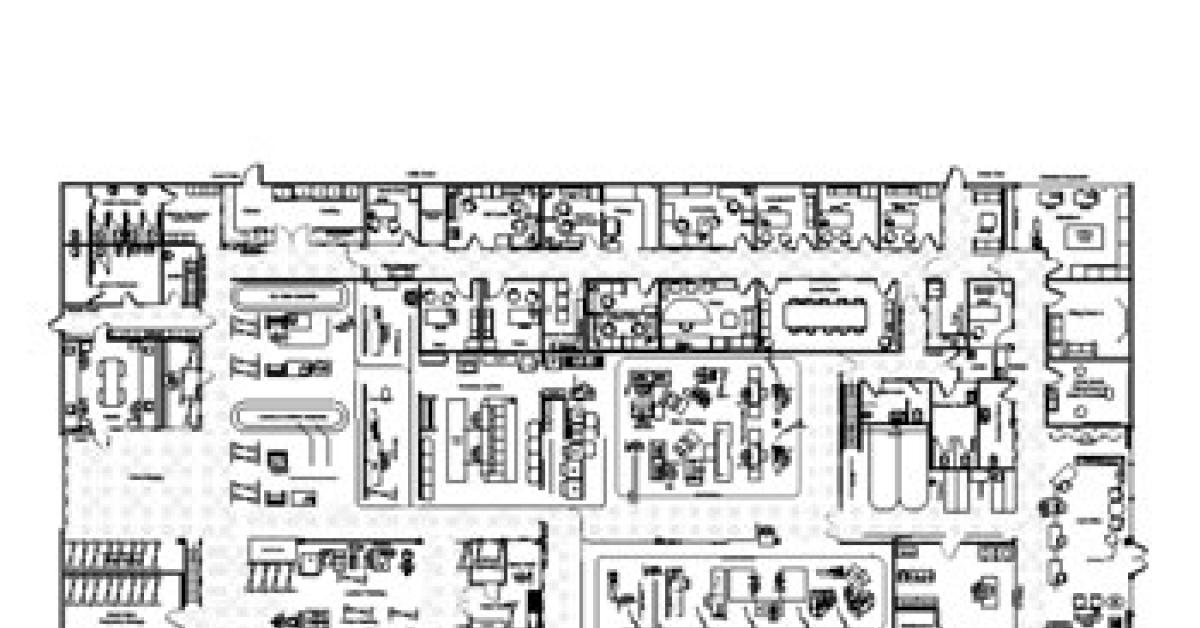

SAN DIEGO — Margaret’s Cleaners’ 22,000-square-foot plant, formerly an upholstery fabric outlet, was designed from the ground up for servicing couture garments and accessories. Work on the two-story structure began in summer 2009 and continues today.

“That’s who we are,” says Chuck Horst, president of the family-owned company and the plant’s designer. “We’re always making changes. I have two departments in a temporary home as we’re still getting the remainder of those departments set up. … The plant is 95% complete.”

Margaret’s services more than 150 fine retailers. It offers delivery throughout Southern California plus Las Vegas, and nationwide through CleanByMail.

THEY DO

Two professional photo studios are available to keep up with photography demands. One studio is used to document wedding gowns and other garments, before and after cleaning and restoration. The other is used exclusively for Margaret’s luxury wardrobe storage and archive service called Garde Robe.

A light table lit from below is used to photograph accessories and footwear. After being processed, the images are uploaded into a client’s password-protected website. Customers utilize their “cyber closet” to request delivery of any of their stored items anywhere in the world.

For delicate and vintage items that can’t withstand the agitation of dry cleaning, a bridal spa, which includes two heated Jacuzzis for soaking and cleaning and a shower for rinsing, is readily available.

Margaret’s has found that drying with air movement produces a softer finish, so a special drying room nearby permits warm-temperature air-drying, assisted by the breeze from an oscillating fan.

Wedding and evening gowns are finished in an air-conditioned clean room. A left-handed drop table press and air finishing boards are utilized to produce a designer showroom finish. Once completed, each gown is checked for latent stains in Margaret’s multi-spectrum inspection room.

Two spectrums of fluorescent light in addition to black lights are used to assure all stains have been removed. Stains that are not evident in ambient lighting conditions can be identified during inspection and removed or re-cleaned.

A recently installed Chicago® flatwork ironer has permitted the company to expand its table/bed linen service. Complemented by a 100-inch Ajax drapery press, Margaret’s can process anything from restaurant-style tablecloths to vintage heirloom lace linens.

An outdoor utility room houses a 50-hp Parker boiler, 35-hp Ingersoll Rand compressor and air dryer, and a car-wash-style central vacuum system. Space is provided for backup equipment for all utilities. The alarmed, lighted room has metal walls that are removable in 15 minutes, providing forklift access.

Water treatment is provided for the entire plant, and uses a European method that doesn’t require salt or maintenance for five years. The first-year inspection of the boiler tubes proved encouraging, giving Margaret’s confidence that the treatment is effective.

With 14 vans on the road, it was a big plus when Margaret’s mechanic asked if he could rent space to perform the maintenance on its fleet on site. A floor lift and tire-changing and -balancing equipment, in addition to a disk and brake lathe, make it possible for most vehicle maintenance and repair tasks to be performed on location.

Keeping the fleet in top condition for drivers is a constant concern. Trucks run daily between San Diego, Orange County, and Los Angeles County, and twice a week to Las Vegas.

The office suite features a formal boardroom that includes video and audio equipment. The enhanced technology permits Margaret’s to conduct virtual meetings and bring all of its locations and offices together. A multipurpose classroom capable of accommodating up to 50 employees for events, meeting and training sessions is frequently utilized.

Horst says he and his family―parents John and Barbara, uncle Fritz, brother Scott, sister Jan and wife Robin, all of whom work full-time at Margaret’s―were pleased to share news of this year’s award with their employees.

Have a question or comment? E-mail our editor Dave Davis at [email protected].