CHICAGO — Flow and efficiency.

Two words to describe the award-winning plant design layout at the new Tide Dry Cleaners store in Sarasota, Florida.

“From the outside to the inside, it’s a beautiful building,” says Robert Lyons, president and CEO of Consolidated Cleaners Inc., the franchisee owner of nine Tide Dry Cleaners (TDC), in Florida, describing its newest plant at 8452 Tuttle Ave., Sarasota.

“The plant flow is efficient, it’s comfortably air-conditioned to benefit both customers and employees, and we provide our customers with the best quality in dry cleaning,” Lyons says.

The Sarasota plant — which is all about workflow, plant efficiency, and the smiling faces of its employees and customers — is the winner of the 2019 Grand Prize in American Drycleaner’s 58th Annual Plant Design Award.

“Parent company Procter & Gamble, known as P&G, got into the services industry with one of its top brands, Tide, with a laser focus on using environmentally safe processes,” Consolidated notes.

It did this by “delivering best-in-class customer service through our carefully selected local franchise partners and through ‘PODs,’ what we call 24-hour service; utilizing access to P&G’s fabricare experts; and creating transparency to where garments are being cleaned.”

Consolidated describes itself as a “highly esteemed group of individuals” that own and operate nine TDC units — seven on Florida’s west coast and two on the east coast — making them one of the top franchisees in the network.

“The group is a mix of family, family friends, and long-time co-workers,” Consolidated adds. “Together they have the ideal structure, with expertise in: site selection, development, accounting, operations, customer service, and the list goes on.”

The new 8452 Tuttle Ave. plant in Sarasota covers 3,000 square feet, accommodates 17 employees, the company notes.

Talking about your scope of services, how does the choice of equipment relate to design and layout?

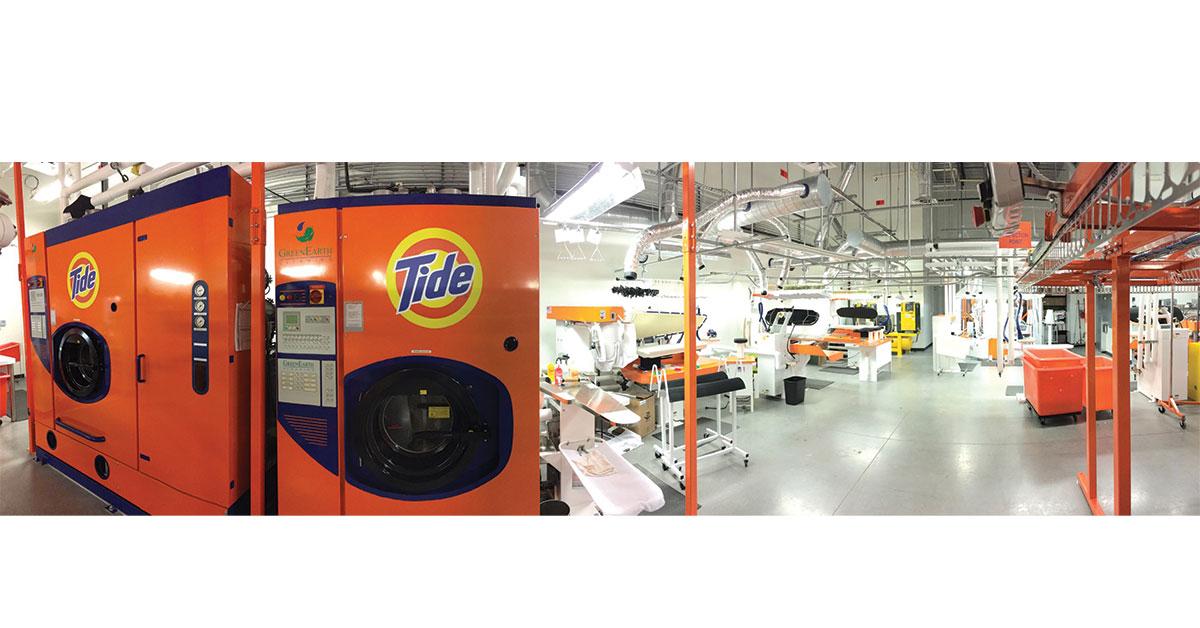

Lyons says: “The Tide Dry Cleaners Sarasota plant design focuses on efficiency and productivity enabling the teams’ focus to remain on exceeding our guests’ expectations with the quality of our cleaning and pressing, the convenience of same-day service with 24-hour access, duel-lane drive-thru valet service and unrivaled guest service with a smile, free bottle of water and P&G Samples.

“We are helping simplify our customers lives and the design of our plant enables us to deliver the convenience, quality and guest service that consistently exceeds our guests’ expectations.”

What influences the decision-making process when placing your plant’s equipment?

“Most importantly for flow is efficiency, creating the fewest steps for our people between stations,” Lyons says. “We want the best plant workflow starting at the front, moving to the cleaning machines, then to finishing. It’s all about efficiency.”

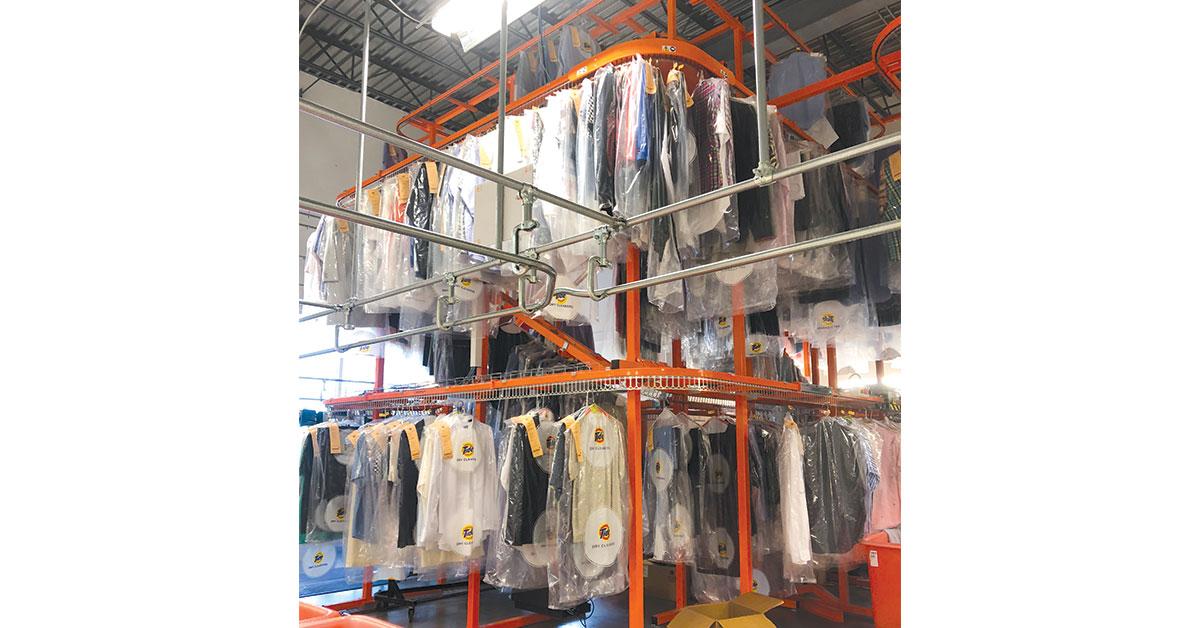

Plant equipment includes installation of Metalprogetti automated conveyor systems. The 20-foot ceilings allowed this to be three levels, the firm points out.

Lyons relates that, “The three-story conveyor allows valuable floor space to be utilized for active production, increasing the efficiency of our space. Maximizing the vertical space is a key component to our plant design.”

Also in the plant are Union drycleaning machines, Unipress pressing equipment, Alliance Laundry Systems (UniMac) laundry equipment, Fulton boiler systems, Kaeser air compressors, and SPOT POS stations.

The plant design and layout was done initially by TDC’s agency development team: “We have an ‘in-house’ designer on the Cushman & Wakefield team,” the company relates.

Check back Thursday for the conclusion.

Have a question or comment? E-mail our editor Dave Davis at [email protected].