CHICAGO — When asked in this first quarter of 2019 American Drycleaner Your Views survey to tell us: “Do you use bar-coding at your drycleaning operation?” 55% responded “Yes,” and 45% “No.”

The survey then asks: “If you don’t use bar-coding, how do you check-in/track items?”

Respondents answer:

- “Software and printed tags.”

- “We will be switching to bar-coding this year.”

- “Strip tags.”

- “Paper tags.”

The survey also asks: “If you do use bar-coding, explain how it works at your store?”

Respondents explain:

- “Heat-seal most all clothing.”

- “Scan the bar-code on the item to create the invoice. If the item does not have a bar-code, we create one that identifies the type of item, color, and brand.”

- “Each item has a specific bar-code where we add: color, manufacturer, damages, or any issue, and so on.”

- “Via our POS software, we mark the garment in and our conveyor system tracks when the items are ready.”

- “We use it to indicate the order is complete and racked, also for inventory control.”

- “All items receive a bar-code upon arrival. This allows us to track each item all the way through the cleaning process. It’s a real game-changer.”

The survey then asks: “If you use bar-coding, are your employees all trained on using your bar-coding system?”

76% say “Yes.” While 24% say “No/NA.”

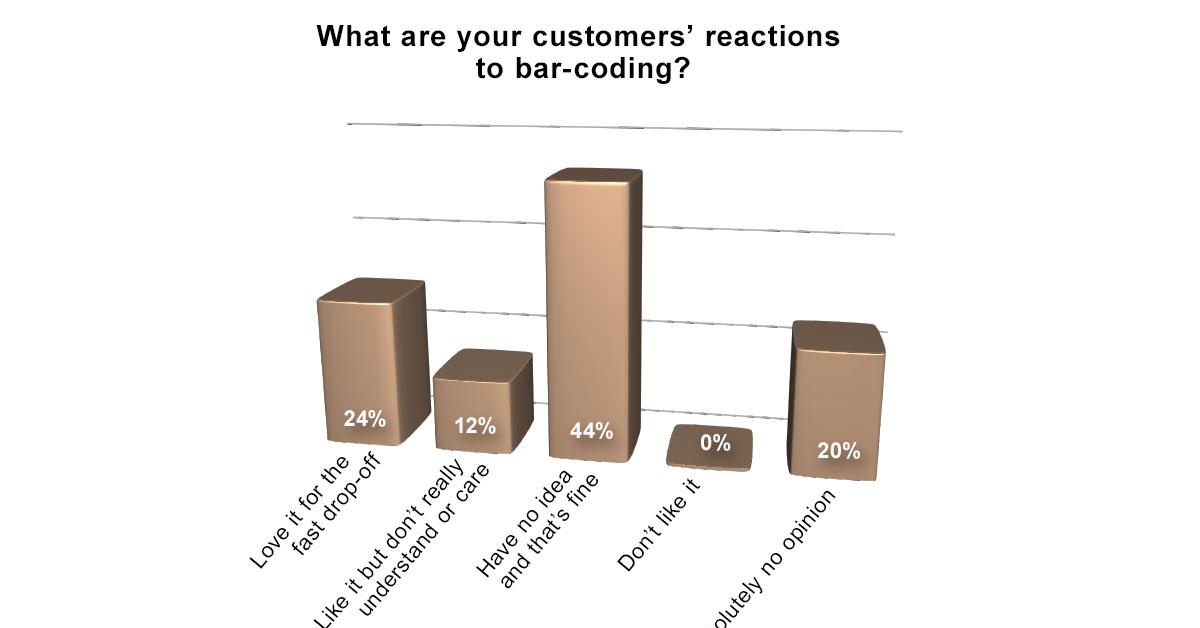

“What are your customers’ reactions to bar-coding?” the survey also asks. “Love it for the fast drop-off,” 24% reply. “Like it, but don’t really understand or care,” 12% relate. “Have no idea and that’s fine,” 44% note. “Have absolutely no opinion,” 20% say. (See graphic.)

Finally the survey asks: “For those who have it, why does bar-coding at your store make such a big difference?”

Respondents share:

- “Able to process more in less time with less mistakes.”

- “It’s an awesome time-saver, much better for tracking assembly and history of items.”

- “We have designated markers trained, and that’s what they do all day long.”

- “Consistent pricing, accuracy of customer garment, plant processing, customer ID.”

- “Makes inventory much easier.”

- “Quick check-in.”

- “Allows us to assemble faster and more efficiently. Also gives us the opportunity to expand with technology as it gets better, faster, stronger.”

- “Faster and more precise mark-in process. No mistakes in the assembly process. It’s also great to have a history of each garment.”

The Your Views survey offers a current snapshot of the trade audience’s views. Qualified subscribers to American Drycleaner e-mails are invited to participate anonymously in the unscientific poll.

Have a question or comment? E-mail our editor Dave Davis at [email protected].