CONCORD, N.C. — Fugitive dye migration is a common problem for both the consumer and the professional cleaner.

In last month’s column, I touched on the “oxidizing bleaches” used in a bleach bath and at the spotting board. A second group of bleaches are “reducing bleaches” that accomplish the job by taking oxygen out of the stain and are commonly referred to as dye strippers.

Sadly, if a cleaner has a dye stripper, it is usually “the purple liquid” that is collecting dust on a shelf. That is the equivalent of a carpenter using only a handsaw because the electric circular saw “is too dangerous.”

The less you attempt to do with a stain, the lower the risk. But the less you attempt to do with a stain, the greater the opportunity for someone else to exploit a perceived weakness in your operation.

Removing the fugitive dye left behind by the consumer, at a premium, should command a mark-up of at least 10%.

Being able to neutralize fugitive dye resulting from a mishandled garment will enhance your professionalism in the eyes of the customer.

GET AGGRESSIVE

A more aggressive reducing bleach is sodium hydrosulfite. This bleach is used in the same manner as sodium bisulfite.

Sodium hydrosulfite has two characteristics that I find appealing. It has the ability to “whiten” white garments beyond the neutralization of chlorine bleach seen with sodium bisulfite.

Sodium hydrosulfite is effective on red dyes like wine and ink. When using sodium hydrosulfite in a bath, you should begin using sodium hydrosulfite in cool water by mixing 1 tablespoon of bleach to 2 gallons of water.

Gradually heat the solution to achieve the desired results. Do not soak the garments, but keep them moving to keep the dye removal even. Rinse the garments thoroughly to remove any residual bleach that could continue to remove additional dye.

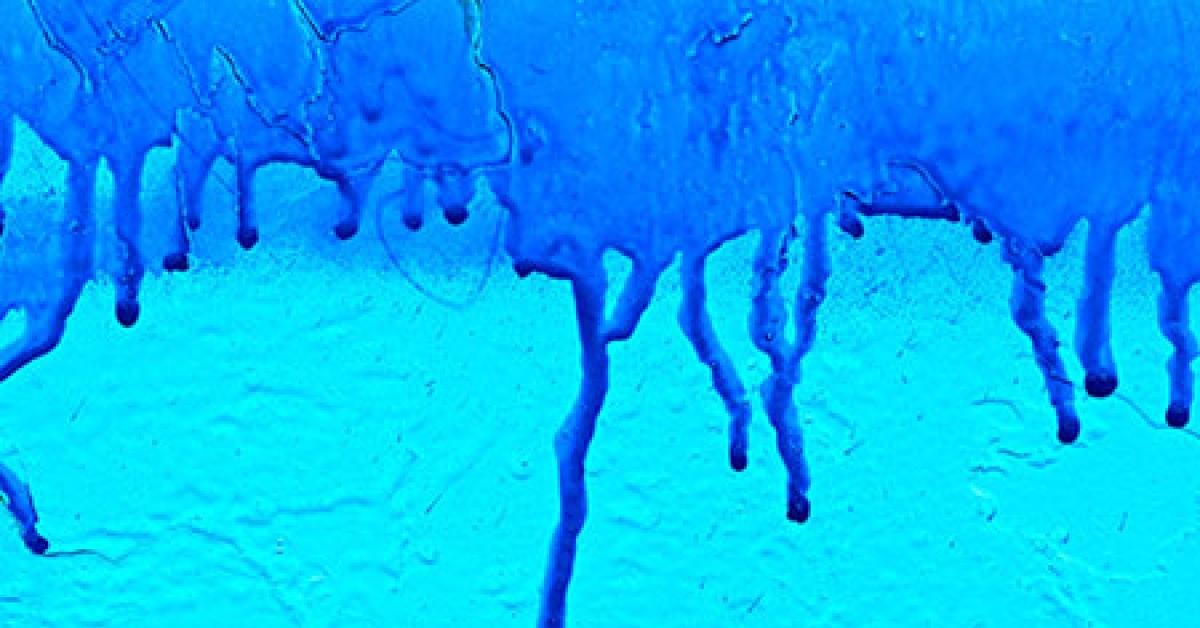

The most common reducing bleach being used is titanium sulfate. This is a dark liquid that appears dark purple to black in color. It is my preferred chemical tool for the removal of residual blue dye and ink.

Applying titanium sulfate at full strength with a wooden toothpick will safely remove the last traces of ink that are currently being returned to your customer with a “Sorry” tag. It can also be used in a bleach bath to remove large areas of fugitive dye.

Mix one ounce of titanium sulfate for each gallon of water used, in water at a temperature of around 100 F. Submerge the garment and keep it moving to ensure even dye removal. Slowly add warm water until the desired results are produced. Rinse the garment thoroughly.

DIE FUGITIVE DYE

Reducing bleaches have a place in garment restoration. They are a valuable chemical tool.

Fugitive dyes can and should be removed by a professional. You just have to make the effort to acquire the knowledge and experience to use these tools for your customer’s benefit.

There is a little trick that can make using any bleach a little safer at the spotting board. This is a mineral oil barrier.

Apply a light coating of mineral oil to the dark side of the original dye using a wooden toothpick, a cotton swab or an eyedropper. When you apply the bleach to the fugitive dye on the light portion of the garment, the mineral oil will block the bleach from disturbing the original dark dye.

Potassium permanganate is a chemical tool that has fallen out of favor over the last 25 years. It is just as good as it ever was but many cleaner/spotters believe it is not worth the effort. I believe it is our job to know more and to do more than the consumer.

This tool will get out stains in white fabric when all else fails.

Flush the stain over the vacuum nose of the spotting board. Apply a small amount of potassium permanganate, full strength, to the stain. Allow the stain to sit for about a minute, then flush the area over the vacuum nose of the spotting board.

You will be left with a tan/brown area that must be neutralized, usually with your rust remover. Flush the area and dry. Apply a leveling agent and run again in the next appropriate run of clothes.

Far too many times, I see cleaners that simply do not make any effort to remove a stain. A vast majority of stains can be removed.

Continuing education will position you in your area to provide the best garment care and therefore be the foundation for continuing success of your business.

To read Part One, go HERE.

Have a question or comment? E-mail our editor Dave Davis at [email protected].